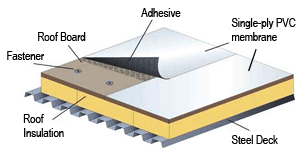

Polyvinyl chloride pvc pvc sheets are produced by calendaring spread coating or extruding and typically are reinforced with polyester or glass fiber mats or scrim.

Thermoplastic membrane roofing pvc.

Our pvc is a flexible thermoplastic membrane manufactured using an ultraviolet resistant polyvinyl chloride.

An example of thermoset membranes includes ethylene propylene diene monomer epdm one of the most widely used roofing systems.

This membrane is best recognized for having the benefits of epdm and pvc systems at a more economical cost.

On the other hand polyvinyl chloride pvc and thermoplastic polyolefin tpo two other common roofing systems for commercial buildings fall in the second category.

These systems are generally categorized as thermoset and thermoplastic membranes.

Pvc membranes deliver a pliable and durable sheet with excellent weathering characteristics and resistance to harsh chemicals and industrial pollutants.

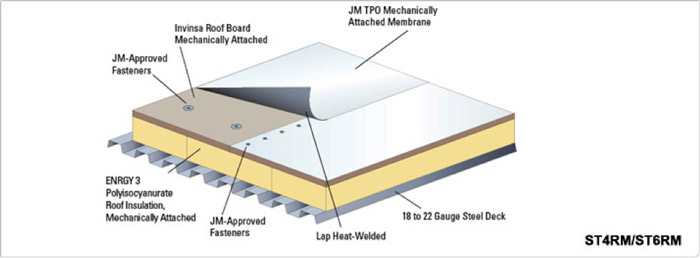

The most common thermoplastic roof membranes are pvc and tpo.

Tpo membranes are white and highly reflective making them an excellent choice for those looking to reduce energy costs.

Tpo membranes are made with a co polymerized rubber that allows them greater flexibility in cold climates.

They are often used for roof recovers and attached over old roofs.

Pvc is a strong material and naturally a reflective white color.

In addition to being energy star rated tpo s recyclability makes it an environmentally conscious system.

Unlike sarnafil which is formulated to perform above and beyond the industry standard sikaplan is formulated to the industry standard like the rest of the thermoplastic roofing membranes on the market.

Over the last few decades pvc polyvinyl chloride thermoplastic roofing membranes have become a primary choice for flat and low slope roofs.