The first test compares the sound absorption performance of a bare unprotected 4 blanket of fiberglass with the same material protected by sheets of perforated metal that required the sound to pass through the perforated sheet.

Sound absorption coefficient of sheet metal around fireplace.

Transmission coefficient τ for walls.

Acoustic panels effectively reduce unwanted noise by helping to disperse it.

Thus for the scope of predicting the exterior sound field for auralization the absorption coef ficient and the scattering coefficient for random incidence are important input data used in room acoustics simulation software.

When sound from a loudspeaker collides with the.

Floor materials 125 hz 250 hz 500 hz 1 khz 2 khz 4 khz carpet 0 01 0 02 0 06 0 15 0 25 0 45 concrete unpainted rough finish 0 01.

The absorption coefficients of materials showed that mineral wool had more normal sound.

Absorption coefficients of common building materials mfg description thickness mounting unit size 125hz 250hz 500hz.

Part of the absorbed energy is transformed into heat and part is transmitted through the absorbing body.

Ipa 107 with 48 open area.

So a coefficient represents a value and they usually measure sound absorption coefficients starting at 125 cycles to 4 000.

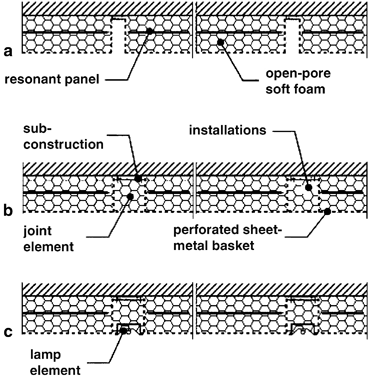

Perforated metal and sound absorptionperforated metal serves a multitude of purposes from lighting to aesthetics.

A typical noise control application involves a combination of absorption of sound and transmission of sound energy by a variety of airborne and stucture borne paths.

A sound absorption coefficient is a coefficient that for those of you out there that understand math it stands for a value.

Sound transmission paths between a room containing a noise source and adjacent rooms some important definitions and concepts.

Predicted random sound absorption coef cient values for mineral wool and galvanized sheet metal frequency hz 63 125 250 500 1000 2000 4000 absorption values of galvanized sheet metal 0.

Then the measures of transmission loss calculated as an overall value for applied absorbent material and bare sheet metal.

Modern buildings especially those located in louder commercial districts face new challenges in controlling noise.

The three perforated sheets were of the following specifications.

In many cases of sound prediction however the absorbed or transmitted energy is a sufficient quantity.

That s a standard test and that s how much energy at that frequency a given material absorbs.

The measured values of noise with one octave band frequency demonstrated an attenuation of 5 5 7 db for these frequencies.

Perforated metal ceiling panel backed with fiberglass 2 e 400 24 x 48 0 63 0 71 0 98 1 11 1 03.

The energy transformed into heat is said to have been lost.